Advanced

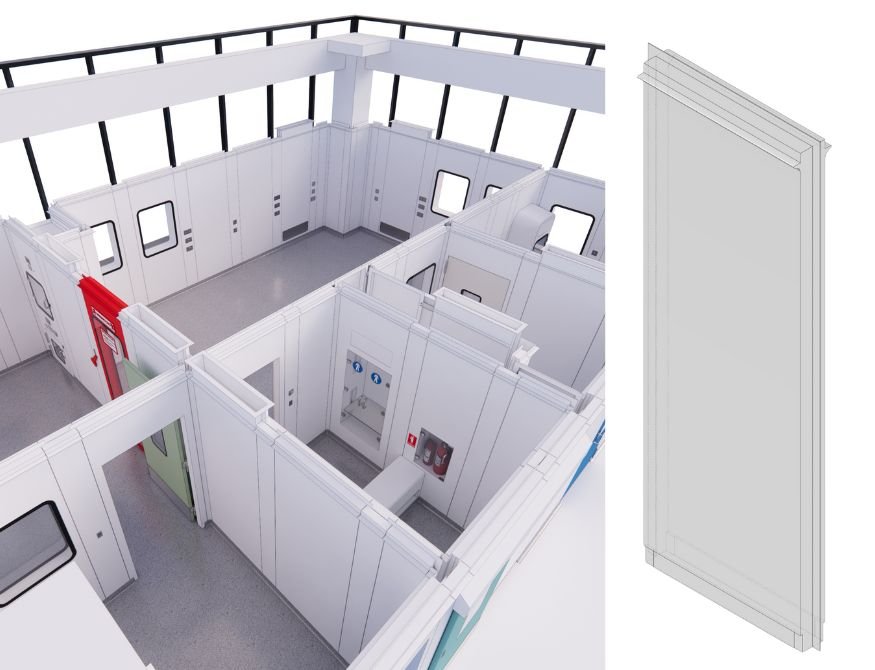

Cleanroom Panel Systems

Our advanced panel systems are designed for high-performance cleanrooms, offering seamless construction, superior hygiene, and long-lasting durability. Built for pharma, biotech, and industrial environments, they provide reliable, compliant, and efficient cleanroom performance.

Product Overview

Advanced cleanroom panels provide a seamless, hygienic, and durable solution engineered for controlled environments. They are designed to deliver long-term performance through a non-porous surface, exceptional chemical resistance, and robust structural strength, ensuring reliability across critical cleanroom applications.

These panels form the core of a cleanroom’s identity — defining its safety, compliance, and operational efficiency. Precision-manufactured and fully customizable, they support ISO, GMP, and industry standards, creating a high-quality, contamination-controlled space that maintains performance for years.

Advanced

Wall Panels

Our Advanced GRP (Glass Reinforced Polyester) wall panels are precision-engineered for modern cleanroom environments, delivering exceptional performance, durability, and regulatory compliance. Manufactured using advanced molding technology and high-grade GRP formulation, these panels create a seamless, non-porous surface that supports the highest levels of hygiene and contamination control. Designed to withstand demanding operating conditions, they offer superior resistance to mechanical impact, chemical exposure, and long-term wear, ensuring lasting reliability in critical applications.

Key Features

- Seamless & Hygienic: A smooth, gel-coated, non-porous surface enables easy cleaning and provides excellent resistance to scratches, stains, and microbial growth.

- Customizable & Versatile: Available in multiple dimensions, configurations, and color options to suit project-specific cleanroom layouts and aesthetic requirements.

- Robust & Durable: Engineered for strength and longevity, these panels deliver over 35 years of performance with outstanding impact resistance and structural stability.

- cGMP & ISO Compliant: Designed in accordance with global cleanroom guidelines, meeting the stringent standards required in pharmaceutical, biotech, semiconductor, and high-tech industries.

- Superior Chemical Resistance: Fully resistant to hydrogen peroxide (H₂O₂) fumigation and more than 120 aggressive cleaning agents, ensuring compatibility with rigorous sanitation procedures.

Service Panels

Our GRP Service Panels are engineered to integrate essential utilities directly within the cleanroom wall structure, ensuring a streamlined, compliant, and obstruction-free environment. Designed with precision and manufactured using high-quality GRP materials, these panels offer a seamless solution for routing cabling, pipework, and technical services without compromising hygiene or aesthetics. Their modular construction and durable finish make them an ideal choice for facilities requiring efficient space utilization and long-term operational reliability.

Key Features

- Optimized Space Utilization: Eliminates the need for external conduits by integrating utilities within the panel system, maintaining a clean and clutter-free workspace.

- Easy Access & Maintenance: Modular design allows quick removal or adjustments, enabling straightforward maintenance and future service modifications.

- Customizable Dimensions : Available in various widths and heights, allowing adaptation to diverse service capacities and cleanroom configurations.

- Seamless Integration : Flush-mounted installation ensures a smooth, uniform wall surface that meets GMP and cleanroom design standards.

Low-Level Extract Panels

Our GRP Low-Level Extract Panels are designed to provide efficient air return within controlled environments, supporting optimal airflow patterns and maintaining consistent room pressure. Manufactured using durable GRP construction and incorporating integrated return risers, these panels ensure reliable ventilation performance while meeting stringent GMP and cleanroom standards. Their streamlined design minimizes the need for bulky ductwork, offering a space-saving solution that enhances both functionality and cleanroom aesthetics.

Key Features

- Integrated Airflow System : Built-in return risers maintain pressure balance and enhance overall ventilation efficiency within the cleanroom.

- Space-Saving Design : Eliminates external ducting, allowing for improved spatial efficiency and cleaner architectural lines

- Easy Cleaning & Maintenance : Accessible from within the room or from above, enabling straightforward cleaning and support for cleanroom hygiene protocols.

- Simple Integration : Standardised duct connections simplify installation and ensure compatibility with a wide range of cleanroom ventilation setups.

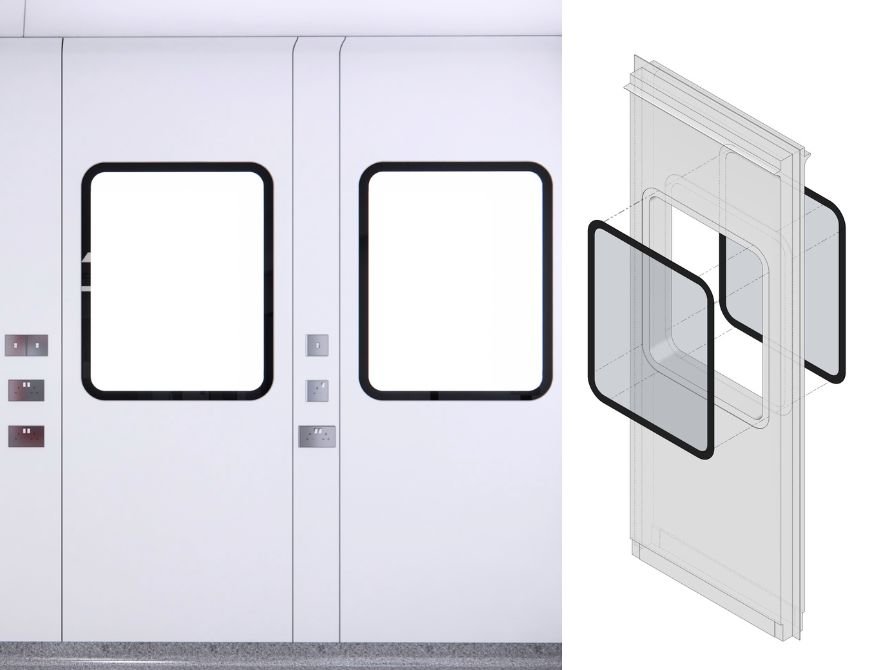

Vision Panels & Windows

Our GRP Vision Panels and Windows are designed to provide clear visibility, seamless integration, and superior hygiene within cleanroom environments. Built using high-quality GRP framing and toughened glass, these panels ensure a flush, smooth finish that aligns perfectly with cleanroom wall systems. Their contamination-resistant construction and durable sealing make them ideal for pharmaceutical, biotech, research, and high-tech applications where cleanliness and clarity are essential.

Key Features

- Flush, Seamless Integration: Installed completely flush with GRP wall panels, ensuring a smooth, frame-free appearance that supports hygienic cleanroom design.

- Hygienic & Airtight Sealing : Secured with FDA-approved silicone seals to maintain cleanliness, prevent particle accumulation, and ensure long-term airtight performance.

- Customizable Sizes: Available in standard and full-height dimensions with options to accommodate diverse cleanroom layouts and visibility needs.

- Durable, Toughened Glass: Equipped with toughened safety glass for enhanced durability, clarity, and impact resistance.

- Cleanroom Compliant : Designed to meet GMP, ISO, and controlled-environment requirements for safety, hygiene, and operational efficiency.

Explore Answers to

Our Most Asked Questions

Yes. Infinity GRP panels conform to global cleanroom requirements including ISO, cGMP, and FDA-aligned specifications, making them suitable for pharmaceutical, biotech, semiconductor, and high-tech facilities. .

Infinity GRP panels are impact-resistant, mechanically strong, and engineered for a lifespan of 35+ years. Their gel-coated surface prevents scratches, wear, and long-term degradation.

Absolutely. The panels are 100% resistant to hydrogen peroxide (H₂O₂) fumigation and can withstand exposure to over 120 aggressive cleaning chemicals, ensuring safe and reliable performance during sanitation.