CLEANROOM

Doors & Ceilings

Our GRP doors, vision panels, and ceiling systems are engineered to deliver seamless performance, exceptional hygiene, and long-term durability within controlled cleanroom environments. Designed for pharmaceutical, biotech, healthcare, and high-tech facilities, each component ensures superior contamination control, structural strength, and compliance with global cleanroom standards. Built to integrate effortlessly into any cleanroom layout, these GRP systems provide a reliable, maintenance-friendly, and aesthetically consistent solution for modern cleanroom infrastructure

Product Overview

GRP doors, windows, and ceiling systems form a core part of cleanroom architecture, providing seamless, hygienic, and durable solutions engineered for controlled environments. Each component is crafted from high-quality GRP materials to ensure resistance to chemical exposure, mechanical impact, and long-term wear.

These systems are designed to maintain strict contamination control, offering flush-mounted surfaces, airtight sealing options, and customizable configurations to support ISO and GMP-compliant cleanroom layouts. Together, they deliver a cohesive, reliable, and high-performance cleanroom ecosystem built for safety, durability, and operational efficiency.

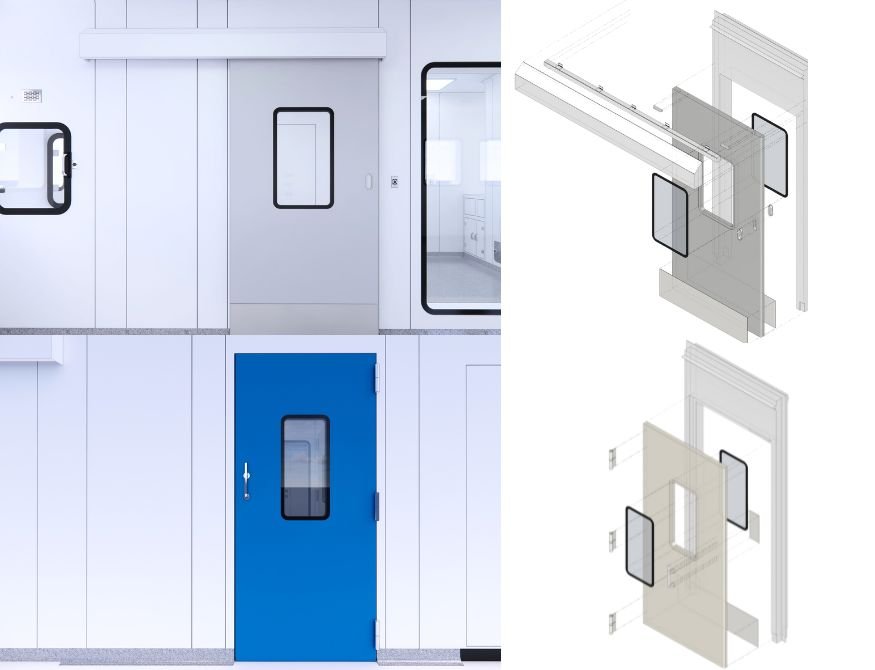

Doors

Our GRP (Glass Reinforced Polyester) doors are engineered to deliver exceptional hygiene, durability, and performance in controlled cleanroom environments. Manufactured using high-strength GRP composites, these doors provide a seamless, non-porous finish that is resistant to chemicals, moisture, and mechanical impact. Designed for demanding pharmaceutical, biotech, medical, and high-tech facilities, they ensure long-term reliability while maintaining strict contamination control.

Key Features

- Seamless & Hygienic:Smooth, non-porous construction prevents particle accumulation and supports easy cleaning, ensuring superior cleanroom hygiene.

- Customizable & Versatile: AAvailable in swing or sliding configurations with customizable sizes, colors, and hardware options to suit varied cleanroom layouts.

- Robust & Durable: Impact-resistant GRP construction with a fully encapsulated high-density core provides strength, stability, and long-term performance.

- cGMP & ISO Compliant: Designed to meet stringent global cleanroom standards for pharmaceutical, biotech, semiconductor, and high-tech applications.

- Superior Chemical Resistance: Zero moisture absorption and full resistance to disinfectants, H₂O₂ fumigation, and aggressive cleaning agents for long-term operational safety.

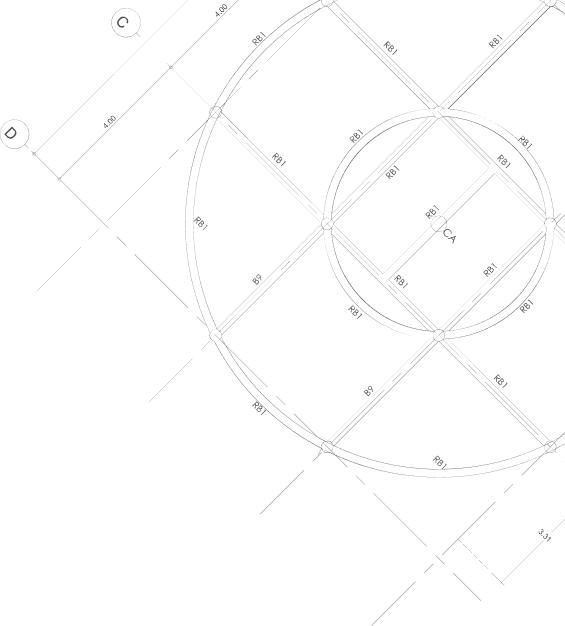

Walk-On / Ceiling Panels

Our GRP Walk-On and Ceiling Panels are engineered to deliver exceptional strength, hygiene, and long-term reliability in controlled cleanroom environments. Designed for load-bearing applications, these panels provide a seamless, robust overhead structure that supports safe maintenance access while maintaining strict contamination control. Manufactured using high-quality GRP composites with precision-molded finishes, they ensure consistent performance across pharmaceutical, biotech, and high-tech facilities.

Key Features

- Highly Durable & Impact-Resistant : Walkable and structurally reinforced, these panels support maintenance activity without compromising integrity or cleanliness.

- Integrated Cut-Outs : Factory-made openings allow seamless installation of lighting, filtration units, and other cleanroom services.

- Seamless Integration: Designed to connect flush with GRP wall panels, eliminating the need for coving and maintaining a continuous, hygienic surface.

- Chemical & Fire Resistant : Certified resistance to hydrogen peroxide (H₂O₂) fumigation and compliant with flame-spread standards (BS476 & ASTM 84 Class A).

- Maintenance-Friendly Design : Panels can be accessed from above or below, ensuring easy cleaning and full compatibility with cleanroom hygiene protocols.

Emergency

Exit Crash Panels

Our Emergency Exit Crash Panels are engineered for rapid and safe egress in cleanroom and controlled environments. Constructed from high-strength GRP (Glass Reinforced Polyester), these panels are impact-resistant and designed with reinforced edges to withstand emergency force while maintaining a hygienic, seamless finish. Built for reliability, they ensure quick evacuation without compromising cleanroom integrity or compliance standards.

Key Features

- Safe & Rapid Egress: Designed with a breakable or push-to-release mechanism that allows immediate escape during emergencies.

- Impact-Resistant Construction : Manufactured from reinforced GRP materials to withstand high-impact force while maintaining structural stability.

- Hygienic & Low-Maintenance: Smooth, non-porous surface supports cleanroom sanitation and resists microbial buildup.

- Customizable Options: Available in multiple sizes and configurations to suit various cleanroom layouts and safety requirements.

- Cleanroom Compatible: Engineered for controlled environments, ensuring compliance with GMP and cleanroom design standards.

Explore Answers to

Our Most Asked Questions

Yes. All GRP doors, vision panels, and ceiling systems are engineered for controlled environments and meet GMP, ISO, and pharmaceutical cleanroom standards with seamless, hygienic construction.

Absolutely. GRP materials are non-porous, moisture-resistant, and compatible with aggressive cleaning agents and H₂O₂ fumigation, ensuring long-term durability and contamination control.

Yes. They come in multiple configurations, sizes, and design options—such as swing/sliding doors, full-height or standard vision panels, and walk-on ceiling formats—to fit specific cleanroom requirements.